6. How The System Works

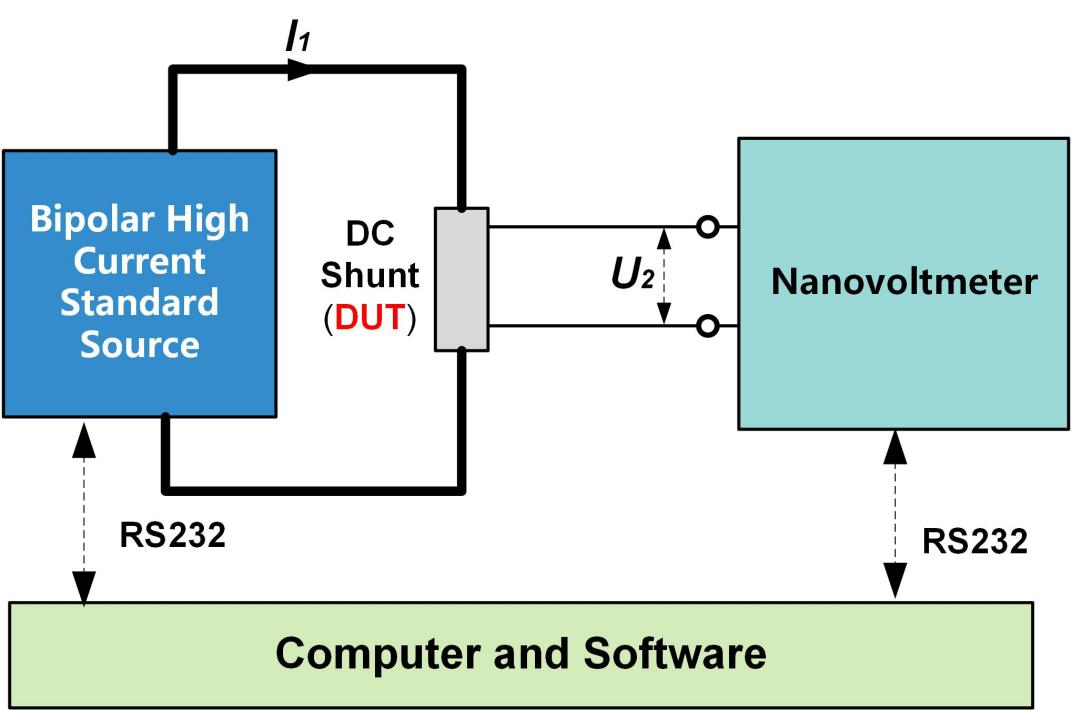

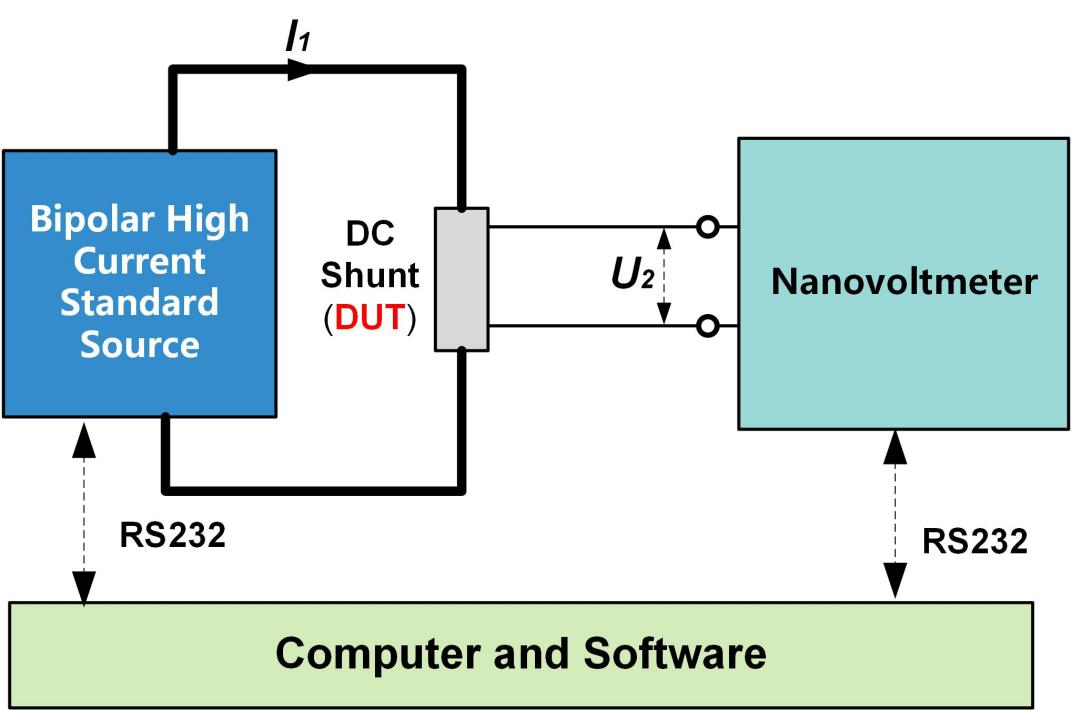

6.1 Shunt Calibration (Direct Measurement Method)

The software automatically controls the rapid commutation of the current source to remove the effects of the thermoelectric potential. This method is suitable for DC shunts with lower accuracy of class 0.02 and below, and can achieve automatic and fast measurement.

Figure 6-1 Schematic Diagram of Calibrating a DC Shunt by Direct Measurement

Description of the test:

• A bipolar high-current source is used to output a standard current as theI1 input to the DC shunt under test.

• Measure the secondary output voltage U2 of the shunt under test directly using a nanovoltmeter.

• After the shunt reaches thermal equilibrium, the resistance of the shunt is calculated according to R=U 2I1.

• After the user has completed the wiring, fully automatic calibration can be realized through the computer and system software.

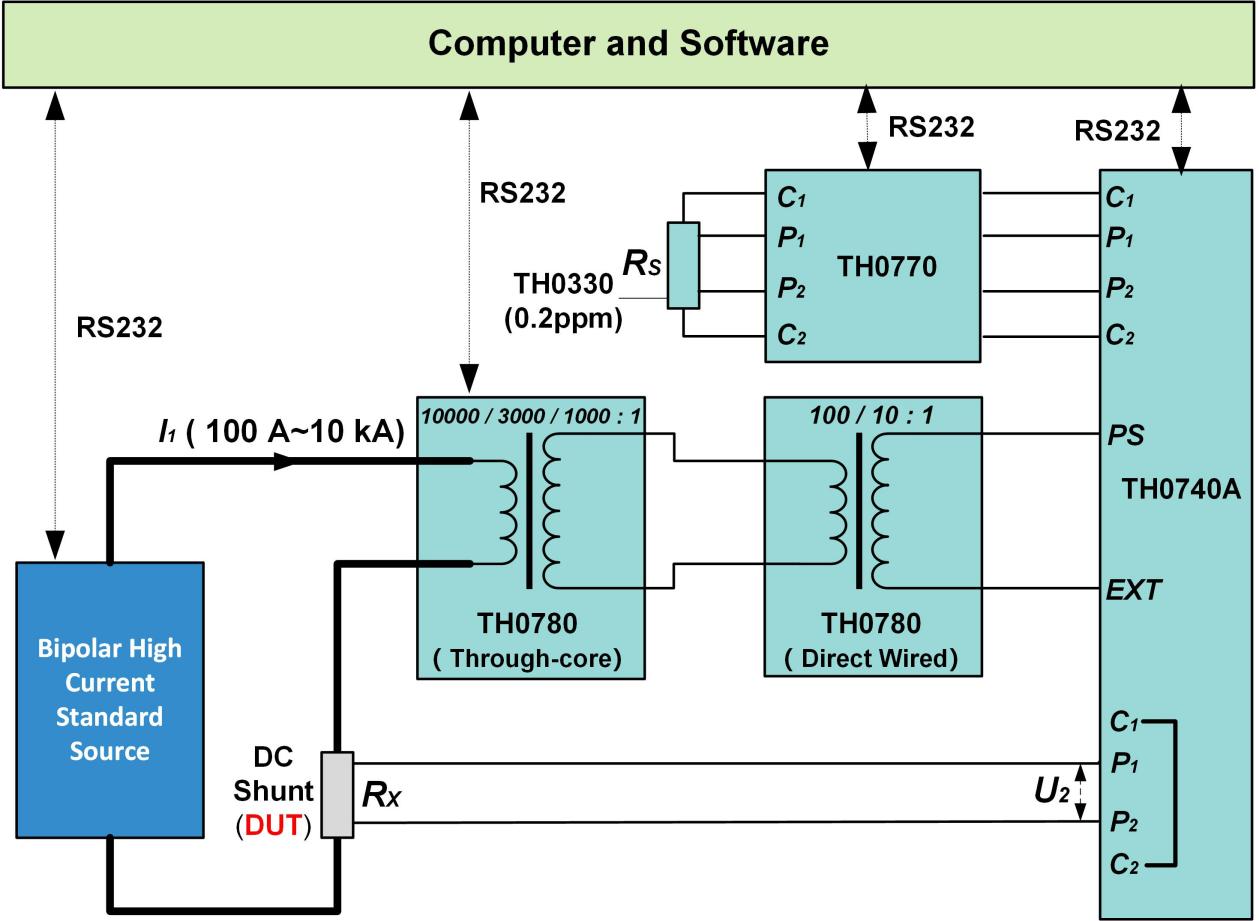

6.2 Shunt Calibration (Comparative Method)

Comparative method features: the use of bipolar high-current standard source with ultra-precision current proportional extender (can be cascaded), ultra-stable standard resistance, standard resistance measurement device through current polarity exchange can achieve ultra-high accuracy resistance transmission, suitable for calibrating 0.02 and above high-precision DC shunt, by the software automatically control the rapid commutation of the current source to remove the influence of thermoelectric potential.

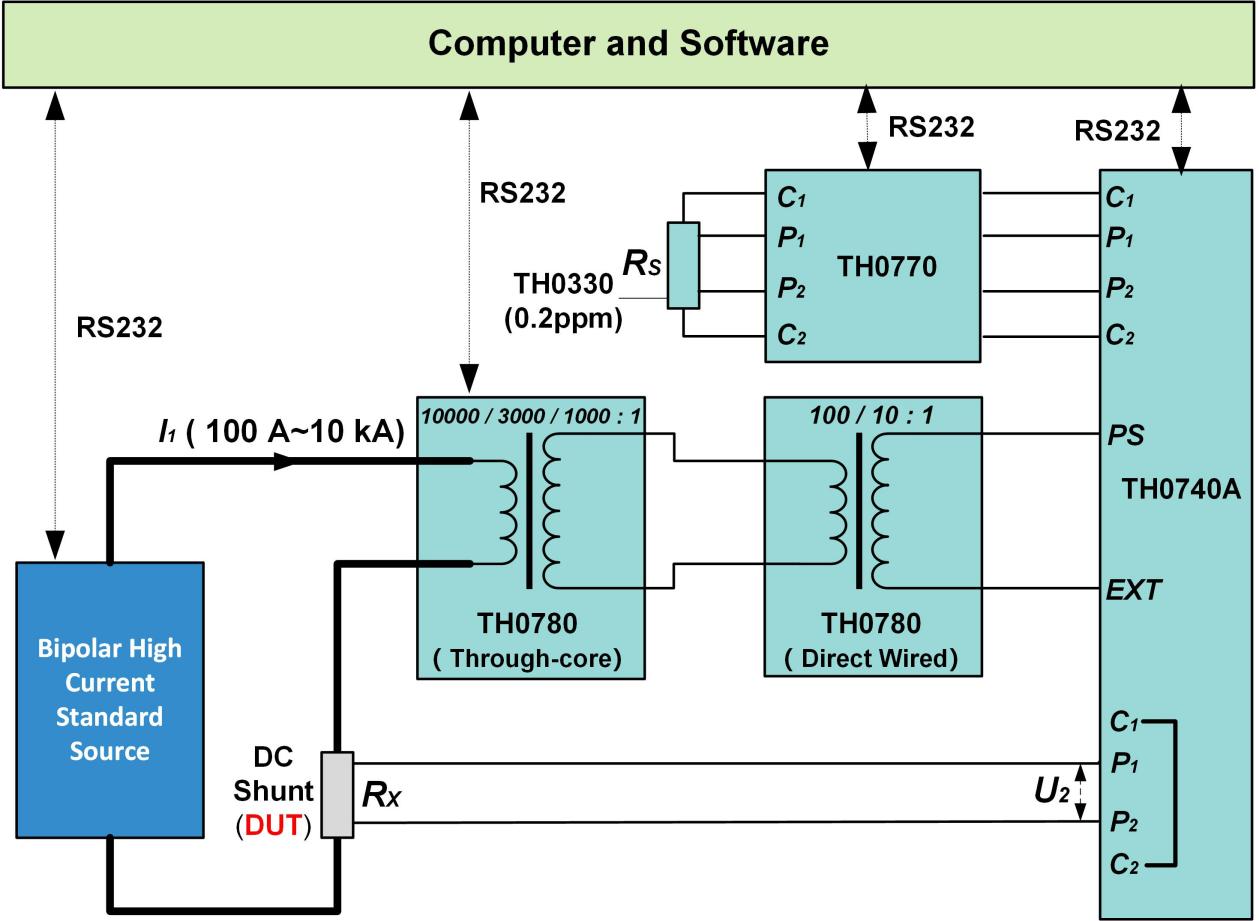

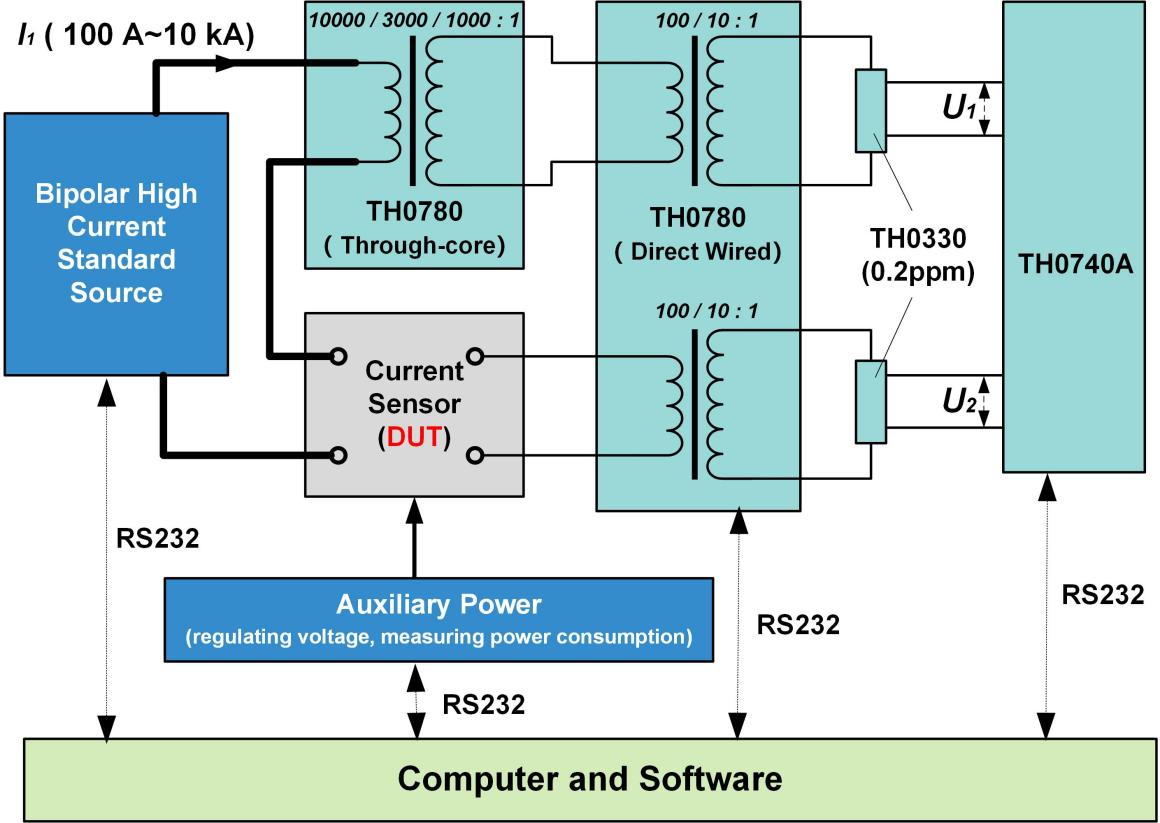

Figure 6-2-1 Schematic Diagram of a Calibrated DC Shunt (I1≥100A) by Comparative Method

Description of the test:

• For DC shunt calibration with nominal current I 1≥100 A, a bipolar high-current source is used to output a standard current as the I1 input to the shunt under test, and 1 000:1, 3 000 are selected according to the input current The TH 0780 ultra-precision current ratio extender of three specifications: 1, 1 0000:1 is connected in series with the primary side of the shunt under test.

• The secondary output of the high-current TH 0780 is connected to the integrated TH 0780 in a dual-channel chassis, and its secondary output is connected to the external excitation input of the TH0740 A.

• Connect the TH0330 ultra-stable standard resistor with a known resistance value to the A channel of the TH 0740 A (the user can program the TH0770 to switch the standard resistor with different resistance specifications).

• The B-channels P 1 and P 2 of the output voltage TH0740 A of the shunt will be shortened to terminals C 1 and C2.

• When the TH0740A internal bridge is balanced, the resistance of the shunt under test is measured.

• After the user has completed the wiring, fully automatic calibration can be realized through the computer and system software.

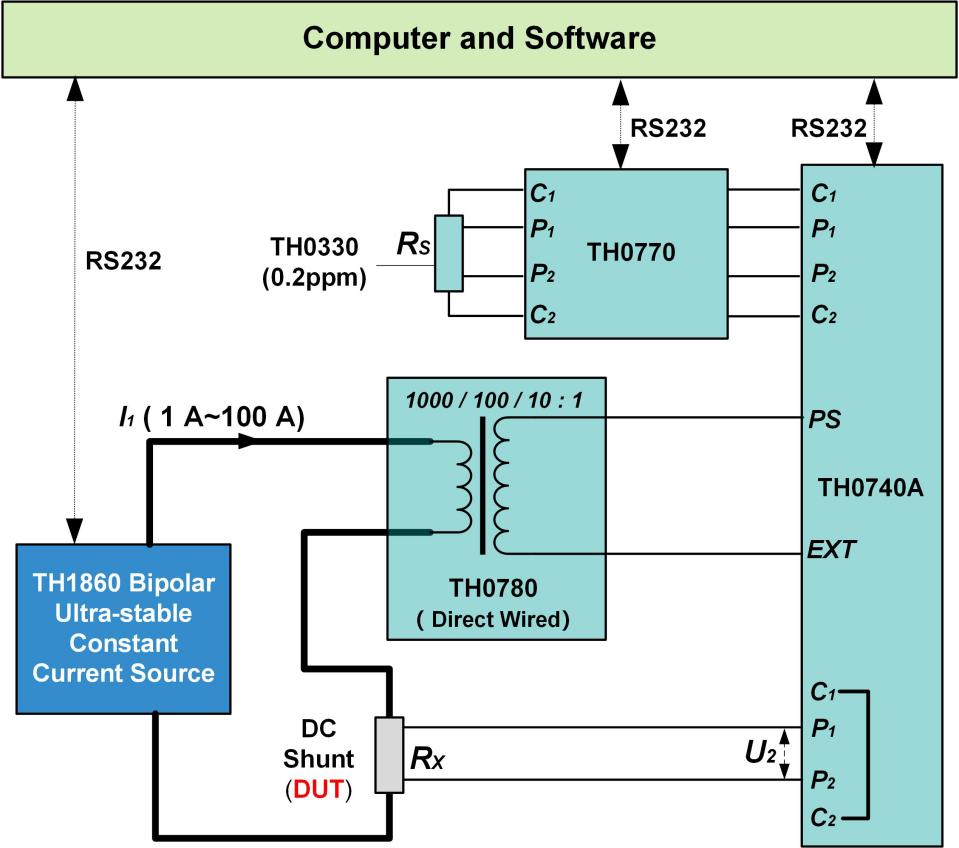

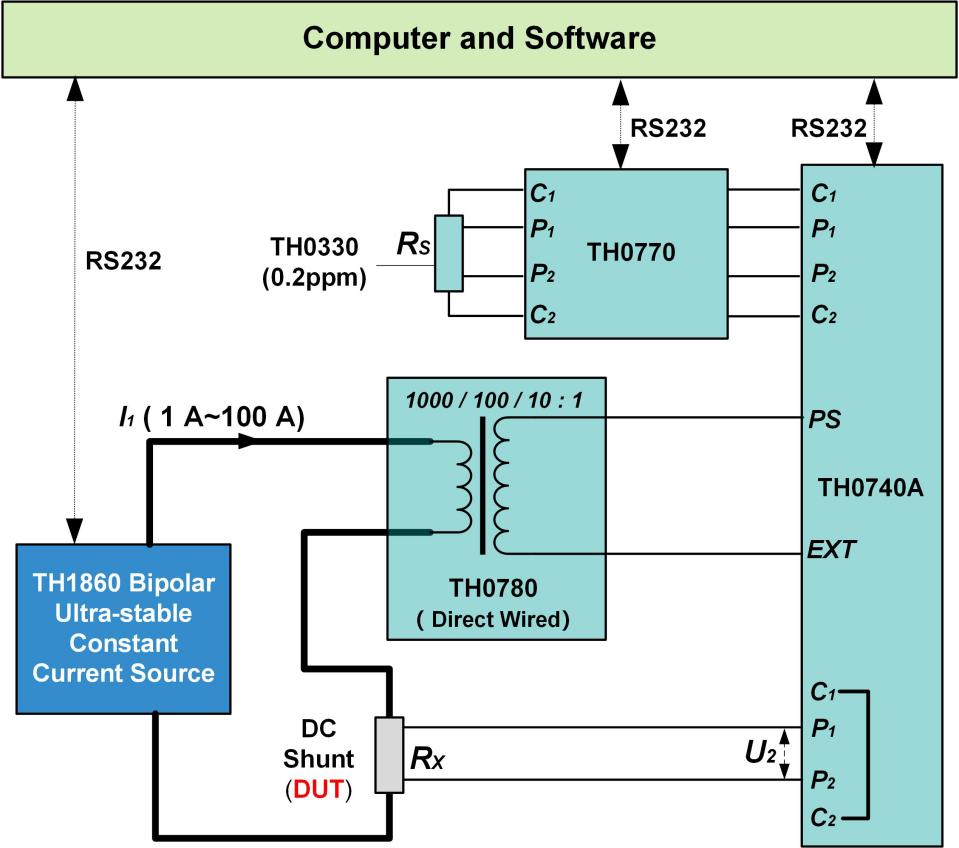

Figure 6-2-2 Schematic Diagram of a Calibration DC Shunt (1 A ≤ I1 ≤ 100 A) by Comparative Method

Description of the test:

• For the calibration of DC shunts with a nominal current of less than or equal to 100 A, the TH 1860 ultra-stable constant current source is used to output a standard current as the I1 input to the sensor under test.

• Pass the I 1 into the primary side of the TH0780 Ultra-Precision Current Proportional Extender (integrated in a dual-channel chassis) and the system automatically selects 1 000:1, 100:1,1 0 based on the input current : 1 scale; Its secondary output is connected to the external excitation input of the TH0740A.

• Connect the TH 0330 ultra-stable standard resistor with known resistance value to the A channel of the TH 0740 A (the user can program the TH0770 to switch the standard resistor with different resistance specifications).

• The B-channels P 1 and P 2 of the output voltage TH0740 A of the shunt will be shortened to terminals C 1 and C2.

• When the TH0740A internal bridge is balanced, the resistance of the shunt under test is measured.

• After the user has completed the wiring, fully automatic calibration can be realized through the computer and system software.

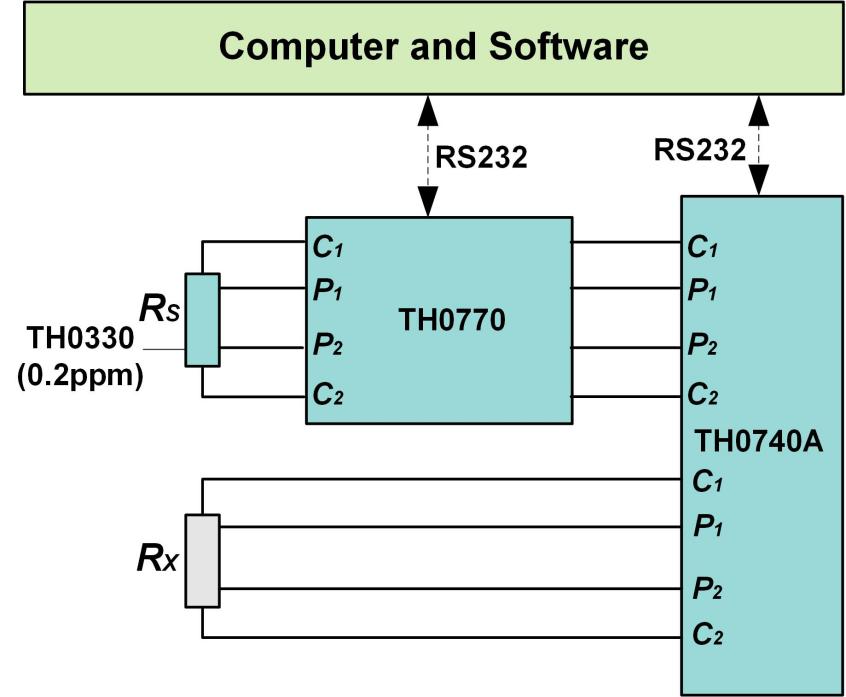

6.3 For DC shunts or standard resistors with nominal current of 0.1 mA ≤ I1 ≤ 1 A, TH 0330 and TH can be used directly 0740A direct calibration.

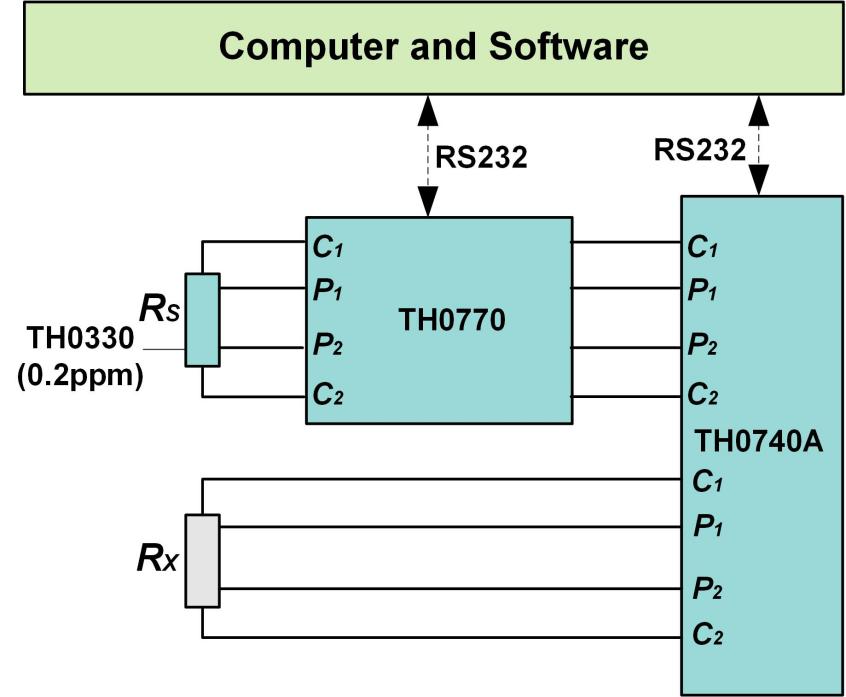

Figure 6-3 Schematic Diagram of a Calibration DC Shunt (0.1mA ≤ I1 ≤ 1 A) by Comparative Method

Description of the test:

• Connect a TH0330 ultra-stable standard resistor of known value to the A channel of TH 0740 A

(Note: Users can switch standard resistors with different resistance specifications through TH0770 program control). 。

• The DC shunt or standard resistor is connected to the B channel of the TH0740A.

• When the TH0740A internal bridge is balanced, the resistance of the shunt under test is measured.

• After the user has completed the wiring, fully automatic calibration can be realized through the computer and system software.

6.4 Sensor Calibration (Direct Measurement Method)

This method is suitable for sensor testing with lower accuracy of class 0.02 and below, enabling fast and automated measurements.

Figure 6-4-1 Schematic Diagram of Calibrating The Sensor by Direct Measurement

Description of the test:

• A bipolar high-current source is used to output a standard current as theI1 input to the sensor under test.

• The current signal I 2 (current type) or voltage signal U2 (voltage type) output by the tested sensor is connected to the secondary signal measurement unit of the sensor, and the primary current I1 is combined to realize the calibration of the sensor ratio.

• After the user has completed the wiring, fully automatic calibration can be realized through the computer and system software.

6.5 Sensor Calibration (Comparative Method)

Comparative method features: the use of bipolar high-current standard source with ultra-high accuracy ultra-precision current proportional extender (can be cascaded), ultra-stable standard resistance, standard resistance measurement device through current polarity exchange can achieve ultra-high accuracy ratio transmission, suitable for calibrating 0.02 level and above high-precision current sensors.

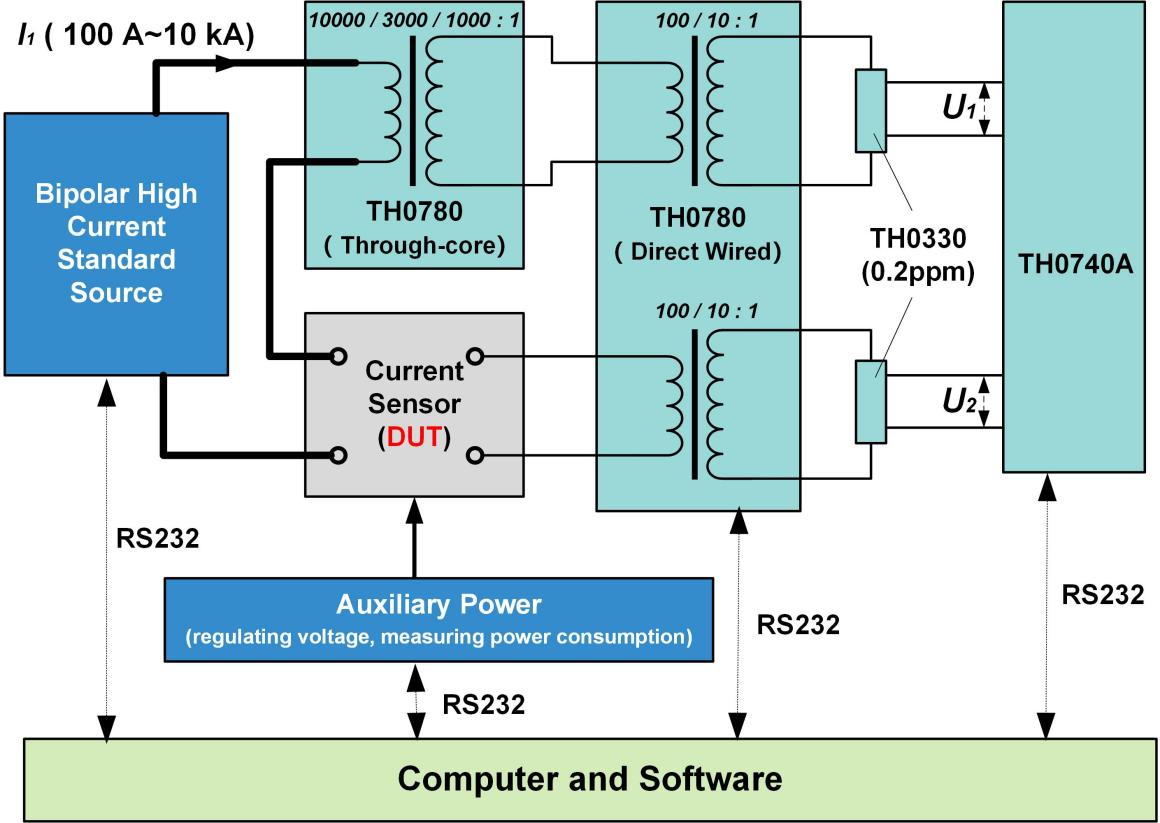

Figure 6-5-1 Schematic diagram of a calibrated sensor (I1≥100A) by comparative method

Description of the test:

• For the calibration of current sensors with a nominal current greater than or equal to 1 00 A, a bipolar high-current source is used to output a standard current as the I1 input to the sensor under test, and 1 000:1, 3 000:1, 10000 are selected according to the input current :1 The TH0780 ultra-precision current proportional extender of three sizes is connected in series with the primary side of the sensor under test.

• The secondary output of the tested sensor and the high-current specification TH 0780 is connected to the integrated TH0780 of the dual-channel chassis, and the secondary output of the dual channel is connected to two TH 0330 ultra-stable standard resistors with known resistance values for I/V conversion.

• Then connect the voltage signals U1 and U2 of the two standard resistors to TH0740A for voltage ratio measurement.

• After the user has completed the wiring, fully automatic calibration can be realized through the computer and system software.

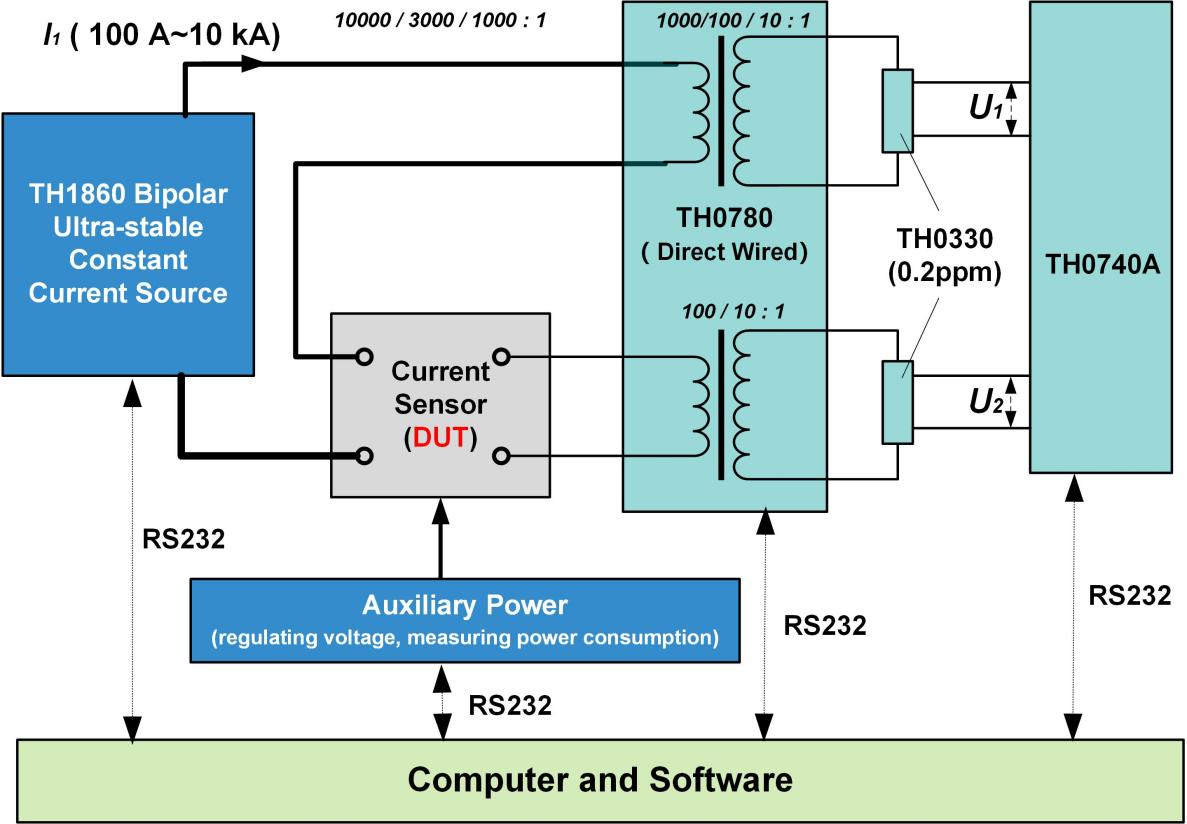

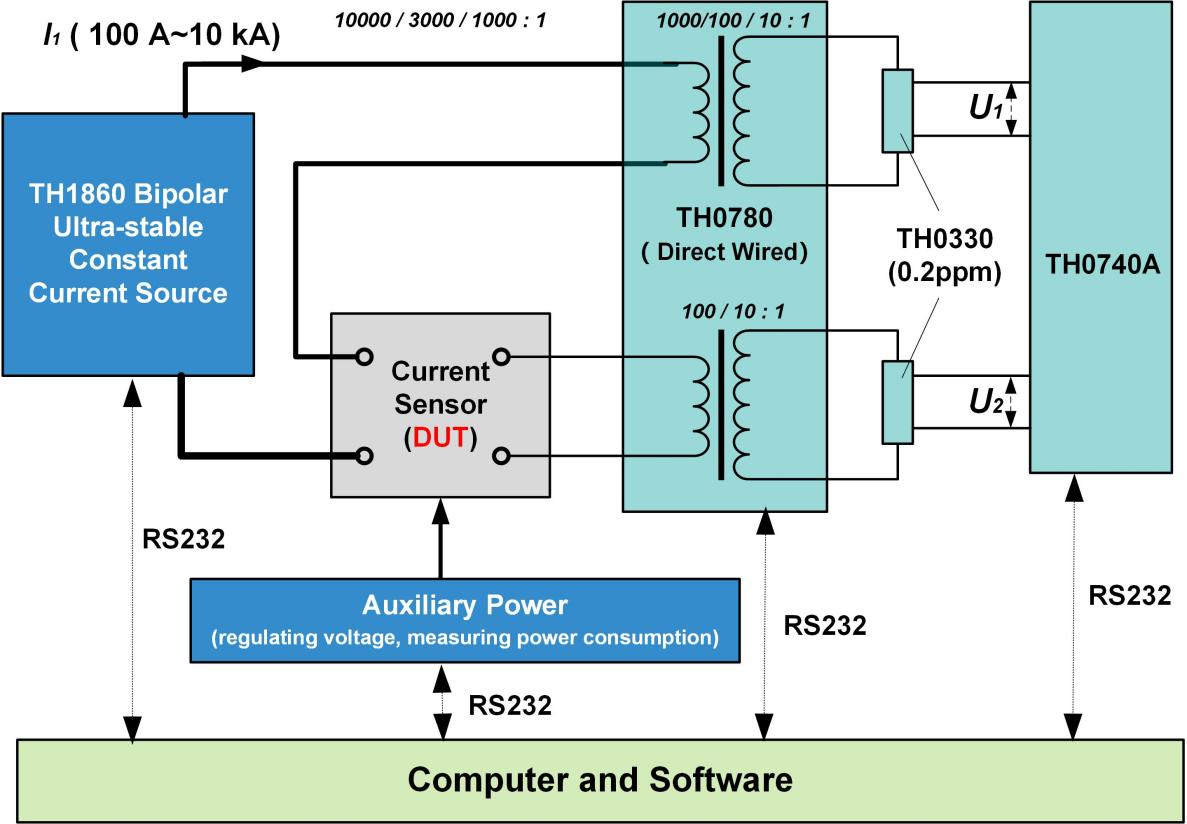

Figure 6-5-2 Schematic Diagram of a Calibrated Sensor (I1≤100A) by Comparative Method

Description of the test:

• For the calibration of current sensors with a nominal current of less than or equal to 1 00 A, the TH 1860-100A ultra-stable constant current source is used to output the standard current as the I1 input to the tested sensor; Pass I 1 into the primary side of the A channel of the TH0780 ultra-precision current proportional extender (integrated in a dual-channel chassis), and the system automatically selects 1 000:1, 100:1, 1 based on the input current 0:1 ratio.

• The secondary output of the sensor under test is connected to the primary side of the B channel of the TH0780.

• The dual secondary outputs of the TH0780 are connected to two TH 0330 ultra-stable standard resistors of known resistance for I/V conversion.

• Then connect the voltage signals U1 and U2 of the two standard resistors to TH0740A for voltage ratio measurement.

• After the user has completed the wiring, fully automatic calibration can be realized through the computer and system software.