In the previous article, we discussed the widespread application of DC power and the importance of its measurement. With the in-depth application of DC power in charging infrastructure, energy storage systems and smart grids, ensuring the accurate measurement of DC power meters has become the key to the development of the industry. Accurate measurement not only affects the fairness of transaction settlement, but also affects the optimization of energy management and regulatory compliance. However, to achieve high-precision DC power measurement, it is far from enough to rely solely on advanced metering equipment. It is necessary to ensure the reliability and consistency of measurement through a complete inspection, calibration and traceability system.

This article will introduce TUNKIA's solution for DC power metering in detail, and explore in depth how the solution ensures the measurement accuracy of DC power meters through strict inspection, scientific calibration methods and traceability systems.

TUNKIA’s DC Energy Metering Solution

TUNKIA offers the most complete DC energy product system that covers four major categories: type evaluation of DC energy meters, working measurement standards, high-level measurement standards, and DC energy reference. This system meets the needs of various application scenarios, including energy meter manufacturers, third-party testing organizations, national metrology institutes, grid companies, and electric vehicle charging pile manufacturers.

1) Type Evaluation Testing Device:

Model | Name | Accuracy |

TE3500 | DC electric energy meter comprehensive testing device | 200 ppm/500 ppm |

TE3600 | DC energy detection device for electromagnetic compatibility test | 500 ppm |

TE3610 | DC energy meter alternating magnetic field test device | Magnetic field generator |

TE3620 | DC energy meter alternating magnetic field test device |

TE3630 | DC energy meter durability test device | -- |

Figure1, 2 DC energy meter constant magnetic field test device

Ensure DC energy meters meet type evaluation standards. Type evaluation is a key certification step before DC energy meters enter the market. TUNKIA provides a type evaluation testing device, that supports multiple testing requirements, including:

a) Power characteristics testing:

Ripple effect, voltage dips, short-term interruptions, ensuring the meter’s reliability under complex power supply conditions.

b) Power consumption testing:

Measures the energy meter's own power consumption, meeting energy efficiency requirements.

c) Electromagnetic compatibility (EMC) and immunity testing:

Testing for power frequency magnetic fields, constant magnetic fields, and electromagnetic compatibility to assess the meter's stability in the presence of external interference.

2) Working Metrology Standard

Model | Name | Accuracy |

TE3000 | DC Energy Meter Testing Device (1 position) | 200 ppm/500 ppm |

TE3100 | DC Energy Meter Testing Device (3-16 positions) | 200 ppm/500 ppm |

TE3200 | DC Energy Meter Testing Device (6-24 positions) | 200 ppm/500 ppm |

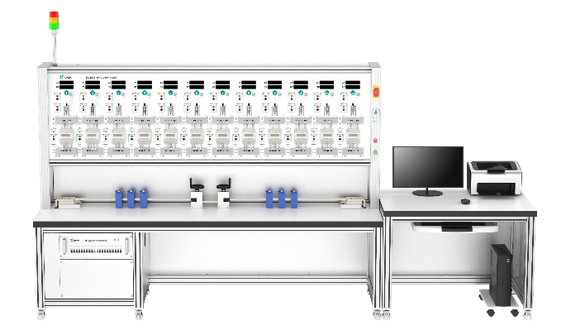

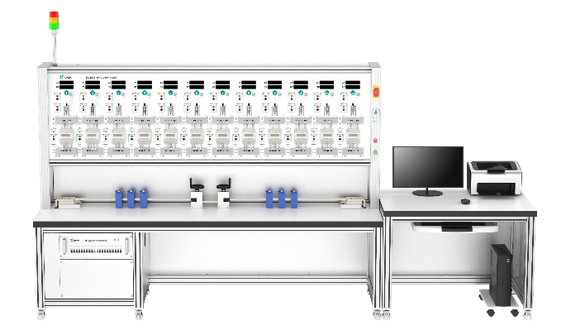

Figure3, 4 DC Energy Meter Testing Device(12 positions&3positions)

Ensure the accuracy of DC energy meters. TUNKIA provides high-precision working metrology standard equipment to meet the routine metrology needs of DC energy meters in calibration and verification processes, including the following testing functions:

a) Basic error:

Tests the measurement accuracy of the energy meter under different working conditions.

b) Starting test:

Ensures the energy meter can measure accurately under minimal load.

c) Creep test:

Prevents false readings from occurring when the energy meter is under no load.

d) Energy constant detection:

Verifies the relationship between the energy meter's pulse output and actual energy consumption.

e) Daily time error:

Assesses the accuracy of the internal clock of the energy meter, ensuring long-term stability of the measurement data. Suitable for energy meter manufacturers, third-party testing organizations, grid companies, etc.

3) High-Level Metrology Standards:

Model | Name | Accuracy |

TH9500S | High Precision DC Standard Power Source | 30 ppm |

TH1300 | AC & DC power energy measurement standards | 50 ppm/100 ppm |

TE3300 | DC standard energy meter calibration device | 100 ppm |

TE2200B | EV charger tester calibration device (for conventional charger) | 100 ppm |

TE2200C | EV charger tester calibration device (for super charger) | 100 ppm |

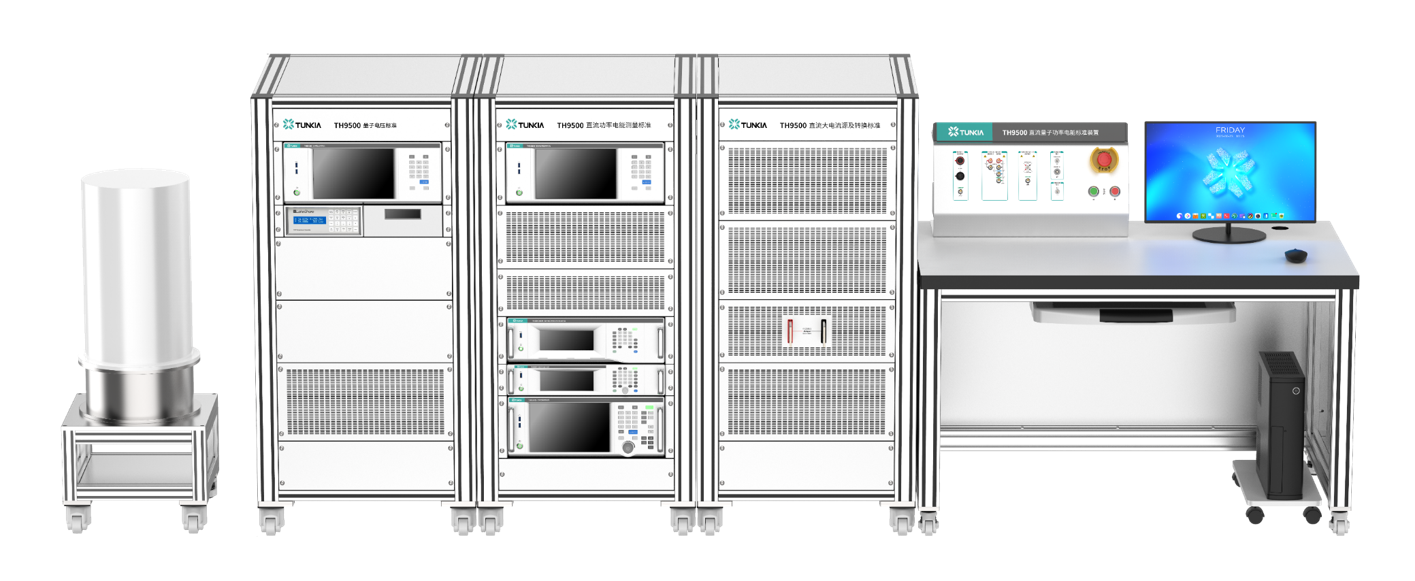

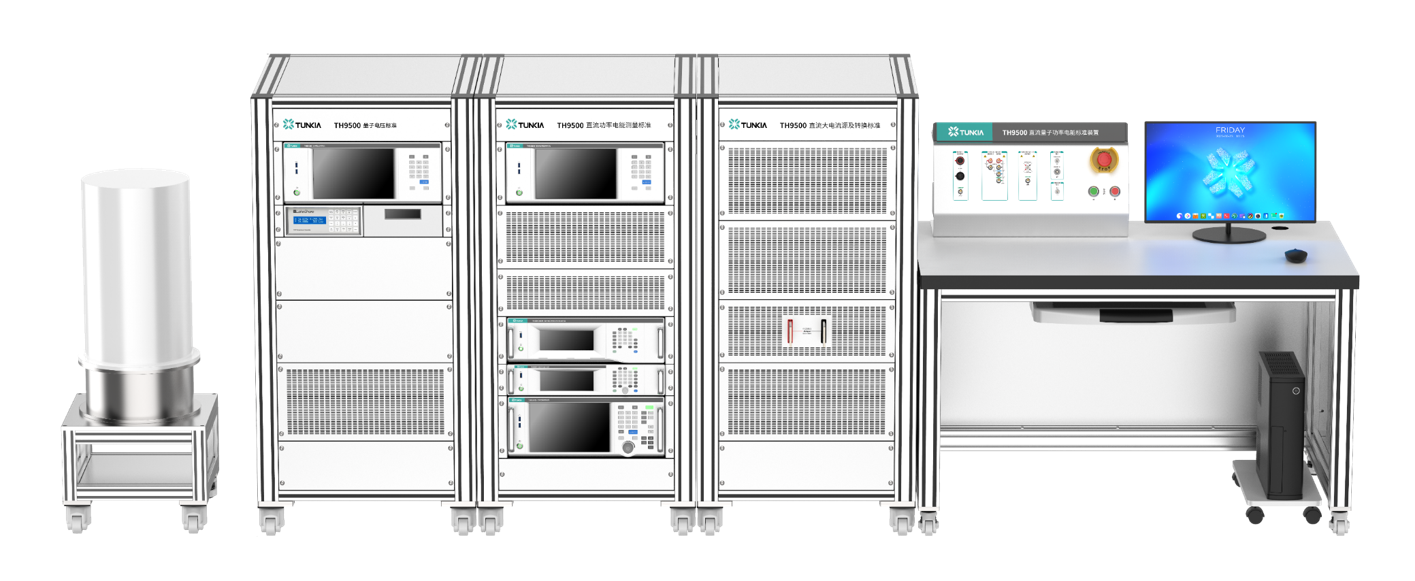

Figure5 TE3300 DC standard energy meter calibration device Figure6 TH1300 AC and DC power energy measurement standards

Accurate traceability to enhance measurement reliability. High-level metrology standards offer higher precision, up to 50 ppm, and are used for:

a) High-precision verification and calibration of DC energy meters, suitable for national or enterprise-level metrology laboratories.

b) Calibration of charging station testing instruments to ensure the measurement accuracy of charging pile metering devices, supporting industry certification.

c) Construction of metrology traceability systems, where high-precision standard equipment can trace and calibrate lower-precision metrology standards, ensuring the traceability of the entire metrology system. Suitable for metrology institutes, third-party laboratories, national grid companies, charging pile testing institutions, etc.

4) DC Energy Reference:

Model | Name | Accuracy |

TH9500 | DC quantum power electric energy standard device | 5 ppm (with PJVS) 10 ppm (without PJVS) |

Figure7 TH9500 DC quantum power electric energy standard device

Quantum-level precision traceability. The DC energy reference adopts the most advanced quantum metrology technology as the top-level reference of the metrology system, providing ultra-high precision:

a) When connected to PJVS (Programmable Josephson Voltage Standard), the precision can reach 5 ppm, ensuring the highest level of traceability.

b) When operating independently, the precision can still reach 10 ppm, making it a core standard device for high-level laboratories. Suitable for national metrology institutes, authoritative certification organizations, and ultra-high-precision metrology research laboratories.

Key Advantages

Based on a complete product system, TUNKIA's DC energy measurement system offers core advantages such as high precision, strong compatibility, wide applicability, traceability, and adaptability to future standards, providing global customers with accurate and reliable metering solutions.

1) Traceability with Complete Product System

Accurate measurement relies on a well-established traceability system. TUNKIA provides a comprehensive metrological hierarchy to ensure all measurement results are reliable and traceable.

• Comprehensive traceability framework: From working measurement standards → high-level measurement standards → DC energy reference, ensuring traceable and verifiable measurements.

• High-precision calibration capability: TH1300 achieves 50 ppm accuracy, making it suitable for calibrating lower-level devices. Therefore, only TH1300 needs to be sent for verification, simplifying the calibration process.

• Meets national traceability standards, supporting third-party metrology laboratories and national metrology institutes.

2) High Precision for Reliable Measurements

High-precision measurement ensures better quality control and reliability. TUNKIA products achieve global-leading accuracy through advanced hardware and signal processing technologies.

• World-Class measurement accuracy: TH9500 achieves 10 ppm accuracy as a high-level metrology standard. When connected to a PJVS (Programmable Josephson Voltage Standard), accuracy improves to 5 ppm, meeting the highest industry standards.

• High-precision time synchronization: TH1300 integrates a synchronous clock with an external rubidium atomic clock, ensuring precise time alignment for consistent multi-device measurements.

• Industry-Leading Technical Specifications for High-Power Applications: Maximum voltage range up to 1500V, suitable for high-voltage DC systems. Maximum current range expandable to 3000A, ideal for EV chargers, power distribution, and industrial applications.

3) High Compatibility and Flexible Applications

Versatile measurement solutions require broad compatibility. TUNKIA systems support a wide range of DC energy meters, from laboratory evaluations to field calibration:

• Supports Various DC Energy Meter Types: Compatible with plug-in and DIN-rail DC energy meters, meeting different industry requirements.

• Adaptable for Both Laboratory and On-Site Use: Provides portable, single-unit calibration devices for flexible use in different environments; Supports both high-precision laboratory testing and fast, efficient field calibration.

4) Efficient Testing for Higher Productivity

Testing efficiency is crucial for both laboratories and field applications. TUNKIA solutions reduce testing time and increase throughput through multi-device calibration and high integration levels.

• Faster DC Energy Meter Calibration: Multi-position test setups support 6, 12, or 18 units simultaneously, significantly improving calibration efficiency.

• High-Efficiency EV Charger Testing: TE3300 enables simultaneous calibration of three devices, making it ideal for large-scale field testing.

• High Integration, Fewer Devices Needed: A single unit can handle most type evaluation tests, reducing the need for multiple devices and simplifying testing workflows.

5) Advanced Modular Architecture for Scalability and Flexibility

TUNKIA adopts IPMA (Integrated Plug-in Modular Architecture), ensuring portability and expandability while maintaining high-performance standards.

• Flexible Testing Methods: Users can select different test methods or expand range and functionality with optional modules, making the system adaptable to diverse applications.

• Optimized Design for Organized Wiring: Fully rear-panel wiring eliminates clutter, improving laboratory workflow and ease of use.

6) Active Role in Industry Standards Development

We play a key role in the drafting of international and national verification regulations, including:

IEEE P2960 Technical Specification for DC Energy Meter Calibration Devices

JJG 842-2017 Verification Regulation for Electronic DC Energy Meters

JJF 1779-2019 Outline of Type Evaluation for Electronic DC Energy Meters

JJG 1186-2022 Verification Regulation for DC Energy Meter Calibration Devices

JJG 1187-2022 Verification Regulation for DC Standard Energy Meters

Reliable Measurement Solutions for a Smarter Future

TUNKIA’s DC electrical energy measurement solutions deliver high precision, full traceability, strong compatibility, and compliance with international standards. Designed for energy meter manufacturers, EV charger testing, power metering, and national metrology institutes, TUNKIA ensures accurate and dependable measurement solutions for the global energy industry.